Introduction:

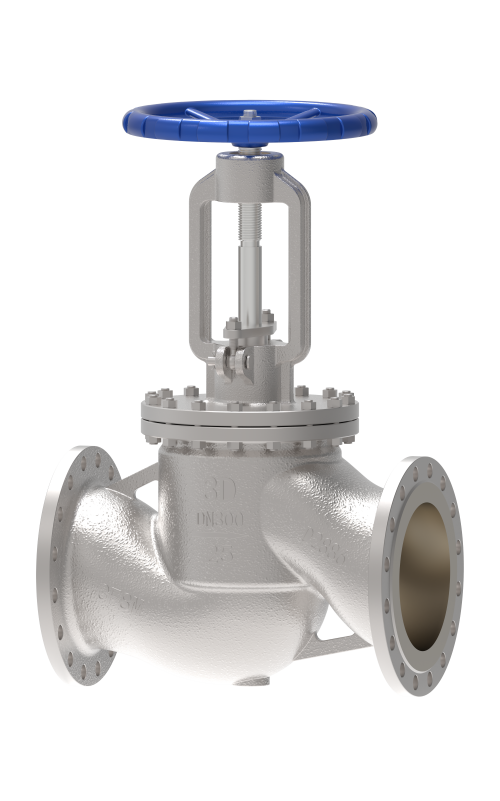

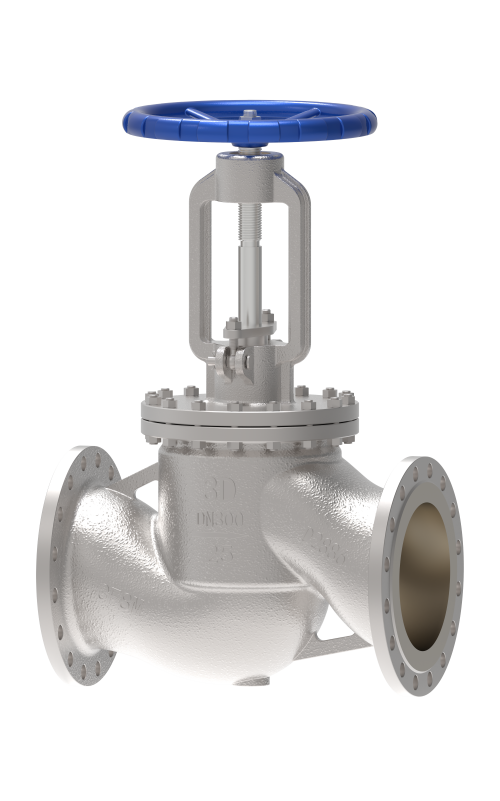

Corrosion-resistant manual globe valves play a crucial role in various industries where controlling fluid flow is essential. These valves are specifically designed to withstand corrosive environments, offering durability and reliability in challenging conditions. This article provides a detailed overview of corrosion-resistant manual globe valves, highlighting their features, applications, and benefits.

Features:

1. Corrosion Resistance: These valves are constructed from corrosion-resistant materials such as stainless steel, alloy, or PVC, ensuring longevity and performance in corrosive media.

2. Robust Construction: Built with sturdy materials and precision engineering, corrosion-resistant manual globe valves are capable of withstanding high pressures and temperatures.

3. Leakage Prevention: Advanced sealing mechanisms and tight tolerances minimize the risk of leakage, maintaining process integrity and safety.

4. Versatile Design: Available in various sizes, pressure ratings, and end connections, these valves offer flexibility to suit diverse applications and installation requirements.

5. Easy Operation: Designed for manual operation, these valves feature ergonomic handwheels or levers for effortless control of flow regulation.

6. Low Maintenance: With simple design and durable materials, corrosion-resistant manual globe valves require minimal maintenance, reducing downtime and operating costs.

7. Compliance: Manufactured according to industry standards and regulations, these valves meet stringent quality and performance criteria for reliable operation.

Applications:

1. Chemical Industry: Corrosion-resistant manual globe valves are extensively used in chemical processing plants to control the flow of corrosive liquids and gases.

2. Petrochemical Industry: These valves play a vital role in petrochemical refineries for handling aggressive substances and maintaining process safety.

3. Water Treatment: In water treatment facilities, corrosion-resistant globe valves are employed to regulate the flow of corrosive chemicals and wastewater.

4. Marine Applications: Due to their ability to withstand saltwater corrosion, these valves find applications in marine systems for seawater intake and discharge control.

5. Pharmaceutical Industry: Critical processes in pharmaceutical manufacturing require corrosion-resistant valves to ensure product quality and regulatory compliance.

6. Mining and Metallurgy: Corrosion-resistant manual globe valves are utilized in mining operations and metallurgical processes for handling corrosive slurries and chemicals.

Benefits:

1. Enhanced Durability: Corrosion-resistant materials prolong valve lifespan and reduce the need for frequent replacements.

2. Improved Safety: Reliable sealing and robust construction minimize the risk of leaks, enhancing operational safety and environmental protection.

3. Cost Efficiency: Lower maintenance requirements and reduced downtime result in cost savings over the valve's lifecycle.

4. Versatility: Suitable for a wide range of applications, these valves offer versatility and adaptability to diverse industrial environments.

5. Regulatory Compliance: Meeting industry standards and regulations ensures compliance with quality and safety requirements, enhancing trust and credibility.