Introduction:

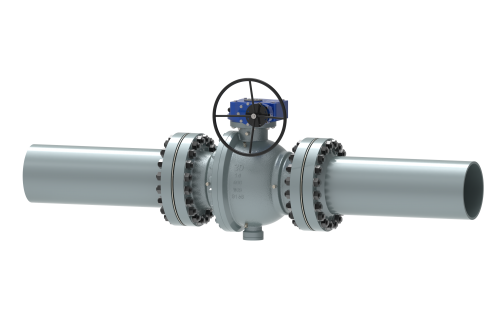

Pipeline cast steel flanged ball valves are crucial components in piping systems for controlling the flow of fluids in various industries, including oil and gas, petrochemicals, water treatment, and power generation. These valves feature a robust cast steel construction and flanged connections, making them suitable for high-pressure and high-temperature applications.

Features:

1. Cast Steel Construction: Pipeline cast steel flanged ball valves are constructed using high-quality cast steel materials, providing excellent strength, durability, and resistance to corrosion and erosion.

2. Flanged Connections: These valves are equipped with flanged ends, allowing for easy installation and connection to piping systems using bolted flange connections.

3. Full Port Design: Many cast steel flanged ball valves feature a full port design, providing minimal flow restriction and maximizing flow capacity through the valve.

4. Fire Safe Design: Some valves are designed to meet fire safety standards, incorporating features such as fire-safe seals and materials that withstand high temperatures.

5. Anti-static Device: To prevent static electricity buildup, which can cause sparks and potentially ignite flammable fluids, some valves are equipped with anti-static devices.

6. Blowout-Proof Stem: The stem is designed to prevent blowout under high pressure, ensuring the integrity of the sealing system and preventing fluid leakage.

7. Adjustable Packing Gland: A packing gland allows for easy adjustment and maintenance of the valve's packing, ensuring reliable sealing and minimizing fugitive emissions.

8. Lever or Gear Operated: Pipeline cast steel flanged ball valves can be operated manually using a lever or with the assistance of a gear operator for easier operation in high-pressure applications.

Working Principle:

1. Shut-off Operation: When the valve is closed, the ball rotates to a position perpendicular to the flow direction, creating a tight seal against the valve seats. This prevents fluid flow through the valve, effectively shutting off the flow.

2. Flow Control: By rotating the valve handle or actuator, the ball can be positioned to modulate flow rates through the valve. Partial opening of the valve allows for controlled fluid flow while maintaining pressure integrity.

3. Pressure Resistance: The cast steel construction and robust design of pipeline flanged ball valves enable them to withstand high-pressure environments without compromising sealing performance or structural integrity.

4. Maintenance: These valves require periodic maintenance to ensure optimal performance and reliability. This may include lubrication of moving parts, inspection of seals and gaskets, and adjustment of packing glands to maintain proper sealing.

Applications:

1. Oil and Gas Industry: Pipeline cast steel flanged ball valves are widely used in oil and gas production, transportation, and refining processes for flow control in pipelines, storage tanks, and processing equipment.

2. Petrochemicals: These valves are essential for controlling the flow of various chemicals and fluids in petrochemical plants, ensuring safe and efficient operations.

3. Water Treatment: Pipeline flanged ball valves play a critical role in water treatment facilities for regulating the flow of potable water, wastewater, and chemicals used in treatment processes.

4. Power Generation: These valves are used in power plants for steam, water, and gas flow control in boiler systems, turbines, and auxiliary equipment.