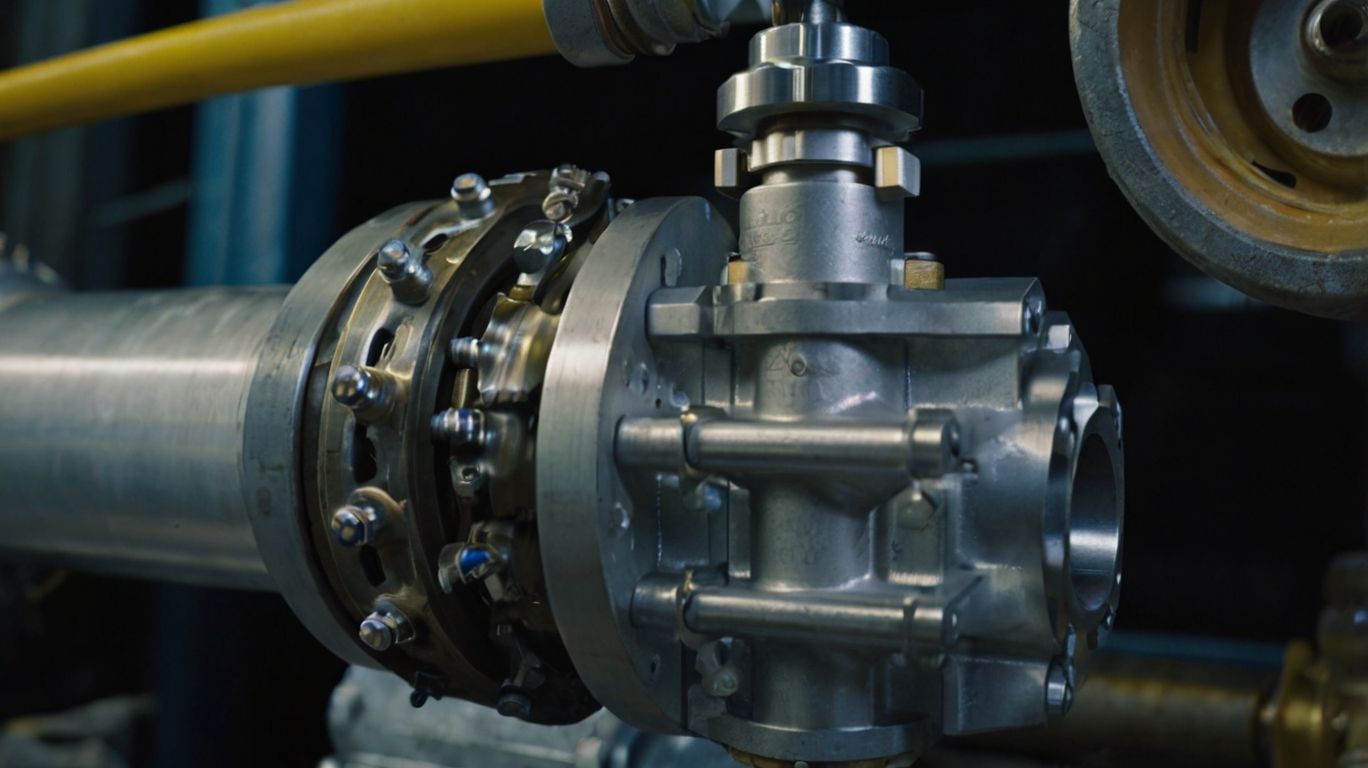

Fluid control systems consist of check valves, which are vital for their functionality. Nearly every pipeline system has these valves, which eliminate backflow and help maintain pressure within the system. In this blog, we will take a detailed look at check valves and how they ensure the seamless operation of industrial pipeline systems.

A check valve, also known as a non-return valve or one-way valve, is a mechanical device that permits fluid (liquid or gas) to flow in only one direction. The valve operates automatically, requiring no manual intervention, electric actuators, or other external means of actuation. The valve opens when fluid flows in the intended direction. When the fluid tries to flow back, the valve shuts itself off automatically against the reverse flow. This mechanism serves as protection against reverse flow or reverse pressure, which can destroy pumps, compressors, pipelines, and downstream equipment.

The principles of operation for check valves aren't new. The earlier-day forms of one-way valves were used as far back as the Roman era, particularly in aqueduct systems, to control the flow of water.

The modern mechanical check valve gained serious importance during the Industrial Revolution, coinciding with the advent of steam engines, water pumps, and other complex fluid systems that required reliable flow control. Along with the growing industrial activity, there arose the demand for check valves with higher efficiency and stronger intent designs. Presently, they are a vital part of everything in the process industries, from oil and gas through food processing and pharmaceuticals.

Check valves have a simple design and perform a basic function, but in the larger context, they are really important pipe components for fluid handling.

That is their primary function: to keep fluids moving in one direction only. Backflow can be dangerous, leading to system contamination, pressure problems, or major equipment failure. Such situations pose threats that check valves automatically protect against.

Reverse flow in systems equipped with pumps or compressors can cause damage to machinery or lead to operational disruptions. Check valves, therefore, act as the safeguard protecting sensitive components from reverse pressure.

Check valves also promote system optimization by ensuring flow in one direction and minimizing unwanted pressure drops that would consume energy; this, in turn, engenders operational stability.

Not employing an external control system or power means that these check valves have a reduced number of moving parts and require a much lower degree of maintenance, compared to other valve types.

They are relatively small, easy to install, and have a long lifespan, which renders them an economically viable solution for preventing backflow.

· Swing check valves open and close their discs in response to flow. It is most preferable for horizontal flow systems.

· Lift check valves have a piston or ball that, with forward flow, lifts off the seat and, with reverse flow, drops back down again.

· Wafer check valves are small, lightweight, and compact designs that fit between flanges in confined areas.

· Ball check valves use a ball for closure. They are primarily used in low-pressure and slurry systems.

· Dual plate or double-door check valves have two spring-loaded plates that open with flow and snap back shut when the flow reverses. They are usually found in high-pressure applications.

· Diaphragm check valves operate with a flexible diaphragm that bends in response to the flow of fluid. It has gained popularity in food industries and chemical-related applications.

Check valves should always be correctly rated for the flow velocity and pressure conditions of your system. Undersizing or oversizing can hinder performance and decrease longevity.

Is your medium a liquid, gas, or slurry? Is it corrosive, abrasive, or sanitary? Each type of check valve is suitable for different kinds of media; hence, material compatibility becomes vital.

The installation of check valves must be according to their design, as some only function properly in a horizontal position. In contrast, others may be properly positioned in a vertical or bi-directional manner. Manufacturer instructions must always be followed.

Cracking pressure is the minimum pressure required to initiate the opening of a check valve. It is essential to choose a valve that will achieve the cracking pressure suitable for your system; otherwise, unwanted delays in flow will occur.

Although check valves require little maintenance, consider a design that will be easy to inspect and repair, thus saving on long-term overhead costs.

Some compact systems may call for wafer-type or inline check valves. Always take space for installation and the type of connection (threaded, flanged, welded, etc.) into consideration.

Used to prevent backflow of contaminated water into clean water supplies. Common in pump stations and municipal water grids.

In high-pressure pipelines, check valves prevent blowback and protect expensive pumping systems and separators.

Check valves are extremely useful for separating multiple chemical feed systems and preventing cross-contamination or mixing between process streams.

The entire duct system utilizes check valves to maintain pressure balance and prevent backflow in heating and cooling loops.

Check valves in fire sprinkler networks maintain water pressure, ensuring that once activated, water shoots in a specific direction.

As industries move toward greater automation and focus on process optimization, smart check valves equipped with sensors and IoT connections are becoming increasingly common. These valves can track flow direction, spot pressure changes, and send data for early maintenance. With the advances in Materials science, all of this is possible. New composite materials and specialized coatings are being developed that enhance corrosion resistance, allowing valves to last longer in demanding environments. These new materials will enable manufacturers to build eco-friendly plumbing that aligns with stricter regulations for energy use and environmental protection.

Although these valves have a simple design, they play a vital role in many systems. Their role in ensuring that fluids flow in the right direction and maintaining pressure in the system to protect pumps and pipes makes them a vital component of any industrial facility. To maximize system efficiency, having in-depth knowledge of valve operations and the benefits they provide is crucial. The right type of check valve can enhance productivity to a new level.